Stage II. Carbon nanofibers and nanowalls deposition. Plasma diagnostic studies at external parameters values defined for carbon nanowalls deposition

Deadline: 28 November 2014

Stage objective

In agreement with the implementation plan, the main purpose of this stage is to achieve carbon nanowalls deposition experiments, and also their morphological and structural characterization. Also, during this stage plasma diagnostic studies at external parameters values defined for carbon nanowalls deposition are made.

Introduction

The most advanced nanostructured materials are the carbonic ones and they can be classified upon their dimensionality [1, 2, 3, 4]. In our previous works [5] we have developed a technique for the deposition of carbon materials in a low pressure radiofrequency expanding plasma jet, injected with acetylene as the carbon precursor, in presence of an active gas (hydrogen).

|

Carbon radicals obtained from the precursor dissociation are transported by the expanding plasma to the heated substrate, where they support the growth process. The method we use is an application of the plasma enhanced chemical vapor deposition. In this present stage we made researches regarding the carbon nanowalls synthesis process and plasma investigation under these conditions, thus defining the carbon nanowalls deposition process. The present research report includes a brief description of the deposition method, followed by the presentation of the results on the properties of the deposited material and the values of the plasma internal parameters obtained when experimental parameters (external) were varied. Also, the synthesized materials were characterized and tested for some applications: carbon nanowalls have useful properties for super capacitors [9], for tribological behavior [10] and cellular carriers [11]. In this stage an international patent was developed on the subject of synthesis method and use for medical devices [12]. The report ends with Conclusion section.

|

|

Technical and scientific description

During the work we tried to establish some correlations between experimental parameters influencing the deposition process (such as argon mass flow and substrate temperature) and plasma parameters (ionic and electronic densities, electronic temperatures, rotational and vibrational temperatures of molecular species) and also how they influence the morphological and structural characteristics of the obtained material. For this purpose, we conducted simultaneously synthesis experiments and plasma diagnostics, during that we varied each parameter, keeping the other parameters constant.

Influence of the carrier gas mass flow over the deposited material and plasma

|

|

|

|

Morphology of the carbon nanostructures synthesized in plasma jet at 300 W, 700 0C but at different argon mass flow. Ar/H2/C2H2 mass flow ratios were: a) 375/25/1 sccm; b) 715/25/1sccm; c) 1050/25/1 sccm; d) 1400/25/1 sccm

|

|

Dimensional characteristics of carbon nanowalls synthesized in plasma jet for different argon mass flow (horizontal low axis) or gas mixture compositions |

|

a) Raman spectra of probes deposited at different argon mass flow and b) bands 2D and G intensities ratio |

|

a) Dependence of emissive species intensities and b) dependence of ratio of C2 (521,16nm), CH (430,87nm), Ha (656,21nm), Hb (486,34nm) intensities at the substrate level and Ar line intensity (696,55nm) as function of argon flow injected in the discharge

|

|

Rotational and vibrational temperatures depending of the argon mass flow |

|

a) Langmuir probe characteristic and b) normalized electron energy distribution functions for different argon mass flows (d = 5 cm, PRF = 300W)

|

|

Plasma parameters evolution depending of argon mass flow: a) electronic temperature and b) electronic density

|

|

Acetylene depletion depending of the argon mass flow (measured from the mass peak of C2H2) |

|

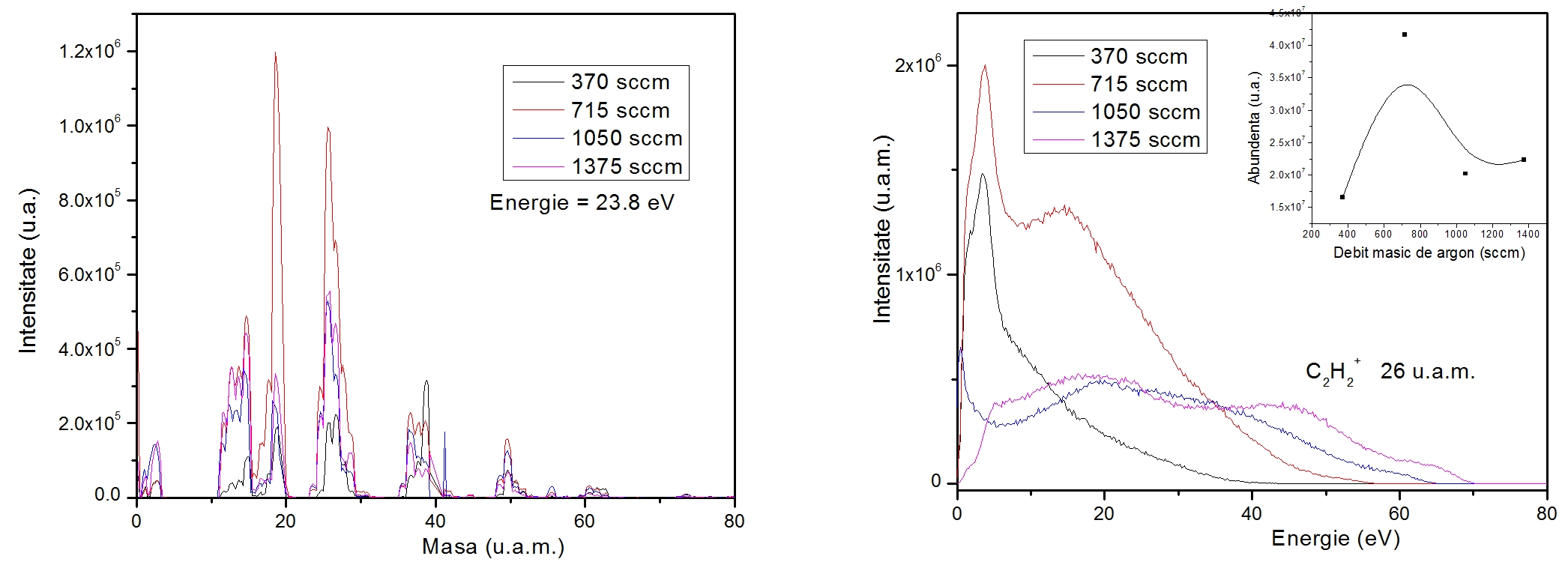

a) Mass spectra for different argon mass flow; b) energetic distribution of C2H2+ ions

|

Influence of substrate temperature on the plasma and deposited material

|

Raman spectra of CNF and CNW like carbonic structures obtained at variation of susbtrate temperature

|

Conclusions

In this stage we studied the deposition process and realized nanostructured carbon material probes in low pressure radiofrequency plasma jet. We showed that the deposited material is made of carbon nano fibers or graphitic carbon nanowalls. In case of carbon nanowalls we showed that they have an average thickness of 30-60 nm and lengths/widths in the 0.4 to 1,4 mm.

We establish the dependence of material characteristics (length, thickness, surface density of carbon structures) of experimental parameters (argon mass flow, gas flow ratios respectively, substrate temperature).

We established by studying the correlation between optimal experimental conditions for obtaining carbon nanowalls (defined by external parameters such as mass flow and substrate temperature) and plasma intrinsic parameters that good quality nanometric walls are obtained at high electron density (1012 cm-3), low electronic temperature (2-3 eV) and high gas temperatures (about 1800 K).

We demonstrated that we can achieve the transition from nanometric fibers to nanometric carbon walls by varying the substrate temperature that allows the approach of the final objective of the project, namely the synthesis of hybrid material.

References

1. M. Terrones, Science and technologies of the twenty-first century: Synthesis, Properties, and Applications of Carbon Nanotubes, Annu. Rev. Mater.Res., 33:419, 2003

2. A. Mostofizadeh, Y. Li, B. Song, Y. Huang, Review Article, Synthesis, Properties, and Applications of Low-Dimensional Carbon-Related Nanomaterials, Journal of Nanomaterials, 2011

3. J.N. Tiwari, R.N. Tiwari, K.S. Kim, Zero-dimensional, one-dimensional, two-dimensional and three-dimensional nanostructured materials for advanced electrochemical energy devices, Progress in Materials Science, 57, 724–803, 2012

4. S. Vizireanu, S.D. Stoica, C. Luculescu, L.C. Nistor, B. Mitu, G. Dinescu, Plasma techniques for nanostructured carbon materials synthesis. A case study: carbon nanowall growth by low pressure expanding RF plasma, Plasma Sources Sci. Technol., 19, 3, 034016, 2010

5. S. Vizireanu, B. Mitu, G. Dinescu, L. Nistor, C. Ghica, A. Maraloiu, M. Stancu and G. Ruxandra, Varieties of nanostructured carbon grown by expanding radiofrequency plasma beam, Journal of Optoelectronics and Advanced Materials, 9, 6, 1649-1652, 2007

6. S. Vizireanu, B. Mitu, C.R. Luculescu L.C. Nistor, G. Dinescu, PECVD synthesis of 2D nanostructured carbon material, Surface and Coatings Technology, 211, 2-8, 2012

7. B. Mitu, S.I. Vizireanu, C. Petcu, G. Dinescu, M. Dinescu, R. Birjega, V.S. Teodorescu, Carbon material deposition by remote RF plasma beam, Surface and Coatings Technology, 180, 238-243, 2004

8. A. Malesevic, S. Vizireanu, R. Kemps, A. Vanhulsel. C. Van Haesendonck, G. Dinescu, Combined growth of carbon nanotubes and carbon nanowalls by plasma-enhanced chemical vapor deposition, Carbon, 45, 2932–2937, 2007

9. T.M. Dinh, A. Achour, S. Vizireanu, G. Dinescu, L. Nistor, K. Armstrong, D. Guay, D. Pech, Hydrous RuO2/carbon nanowalls hierarchical structures for all-solid-state ultrahigh-energy-density micro-supercapacitors, Nano Energy, 10, 288–294, 2014

10. D.L. Cursaru, S. Vizireanu, S. Mihai, D. Ghiţă, D.S. Stoica, G. Dinescu, Friction and wear properties of carbon nanowalls coatings, Digest Journal of Nanomaterials and Biostructures, 9, 3, 1105 – 1114, 2014

11. E.C. Stancu, A.-M. Stanciuc, S. Vizireanu, C. Luculescu, L. Moldovan, A. Achour, G. Dinescu, Plasma functionalization of carbon nanowalls and its effect on attachment of fibroblast-like cells, Journal of Physics D: Applied Physics 47, 265203, 2014

12. Dr. Ita Junkar, Dr. Martina Modic, Dr. Alenka Vesel, Prof. Dr. Gheorghe Dinescu, Dr. Sorin Ionuț Vizireanu, Dr. Silviu-Daniel Stoica, Prof. Dr. Karin Stana Kleinschek, Prof. Dr. Miran Mozetic, Method of growing carbon nanowalls on a substrate, depus în Marea Britanie pe 13.10.2014, cu numărul 1418056.6

13. A. Lazea-Stoyanova, M. Enculescu, S. Vizireanu, V. Mărăscu, G. Dinescu, Effects of process parameters on growth of metal particles by atmospheric pressure plasma jet, Digest Journal of Nanomaterials and Biostructures, 9, 3, 1241 – 1247, 2014

14. E. Abdel-Fattah, M. Bazavan, H. Sugai, Langmuir probe diagnostics of electron energy distributions with optical emission spectroscopy in capacitively coupled rf discharge in nitrogen, Journal of Applied Physics, 110, 113303, 2011